For the beginning percussionist as well as the orchestral player, having the right mallet is vitally important to achieving the desired tones. At Allstates Rubber & Tool Corporation, we worked with a top manufacturer of mallets to create a range of durable rubber mallet heads geared towards specific applications.

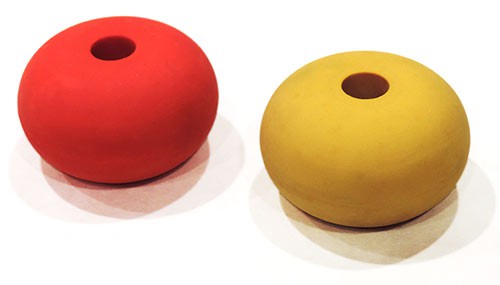

Using a combination of compression and injection molding processes, we mold the mallet heads in sizes ranging from 7/8” to 1-½” in diameter. We also make them with a “hockey-puck” design for kettle drum applications. Differences in material hardness produce variations in tone, so we mold a variety of compounds using either natural rubber (for spring) or Nitrile, in a range from 40 to 98 durometer. Experience has taught us that in the higher durometer readings, Nitrile provides a better flow of material into the mold and protects against pits or voids that could affect sound quality. We vary the color of the compounds to provide easy visual identification of the different hardness ratings of the mallet heads. By keeping tolerances of ±.010” or better, we ensure a tight fit of the head to the handle.

Using a combination of compression and injection molding processes, we mold the mallet heads in sizes ranging from 7/8” to 1-½” in diameter. We also make them with a “hockey-puck” design for kettle drum applications. Differences in material hardness produce variations in tone, so we mold a variety of compounds using either natural rubber (for spring) or Nitrile, in a range from 40 to 98 durometer. Experience has taught us that in the higher durometer readings, Nitrile provides a better flow of material into the mold and protects against pits or voids that could affect sound quality. We vary the color of the compounds to provide easy visual identification of the different hardness ratings of the mallet heads. By keeping tolerances of ±.010” or better, we ensure a tight fit of the head to the handle.

The clean seams on our products are what make them really stand out. We have developed a process to reduce flash and effectively grind or smooth out the seams, which gives the part a better appearance while enhancing overall musical performance. Our range of products allows this client offer their customers budget-conscious solutions for students at all levels of learning as well as highly engineered products that meet the demands of today’s most accomplished percussionist.

To learn more about this project or our rubber molding capabilities, contact us today.