The Allstates Rubber and Tool Team is proud to go above and beyond for our customers. In the spirit of offering low cost, flexible options for nearly 50 years, we’ve developed a variety of manufacturing capabilities to serve the needs of every project, from molding to fabrication to extrusion.

What is Thermoplastic Rubber Extrusion?

Thermoplastic extrusion begins with combinations of raw plastic, rubber and resin materials. Standard construction can be singular or customized with up to three materials in a custom blend.

Thermoplastic extrusion begins with combinations of raw plastic, rubber and resin materials. Standard construction can be singular or customized with up to three materials in a custom blend.

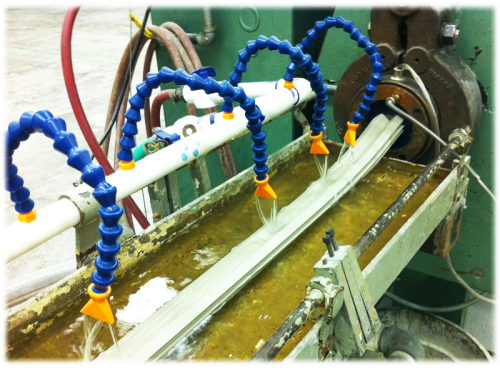

The production process is typically continuous — raw material, fed into the extruder, is forced under pressure through a die, forming the profile or shape of choice. The resulting part is then fed from the end of the extruder into cooling air or water tray for stability.

The simplicity of this process allows for the combination speed and efficiencies to produce. The varieties of profiles we can run are endless and span across a wide variety of industries including home, automotive and industrial components.

Sizes and Tolerances

Cross sections range from 3/64” to 3.5” in diameter, with tolerances for cross sections about .015” and length dictated by the cut length.

Profiles we can extrude include:

- Tubes

- Custom Profiles

- Rods / Cords

- U Channels

- P-strips, E-strips or D-strips

Materials

Thermoplastic rubbers with a durometer of 40 to 80 are ideal for extrusion. These specialized rubbers typically incorporate vinyl or PVC in some capacity.

Industries and Applications

The versatility of thermoplastic rubber extrusion provides valuable parts to an assortment of industries, especially those demanding seals to maintain temperature or air quality.

- Medical and FDA compounds

- Aerospace

- Electronics

- Food contact, storage and transportation

- Automotive

- LED lenses

- Consumer and home goods

If you are interested in learning more, please contact us directly.

Additional Information

Extrusion Profile Width

Min-3/64”

Max- 3 ½”

Extrusion Products

Cord

U Channels

P Strips

S Strips

E Strips

L Strips

T Strips

Door Seals

Gaskets

Rectangular Bumpers

Bulb Seals

Corner Pieces

Typical Lead Times Available

3-5 Weeks

Industry Standards

American Society for Testing and Materials

Food And Drug Administration

International Organization for Standardization

Military Specifications

Restriction Of Hazardous Substances (Compliant)